High performance worm gear reducers are an integral part of many industrial processes, providing efficient power transmission and reliable torque multiplication. These gear reducers are designed to handle heavy loads and provide high efficiency, making them suitable for a wide range of applications across different industries.

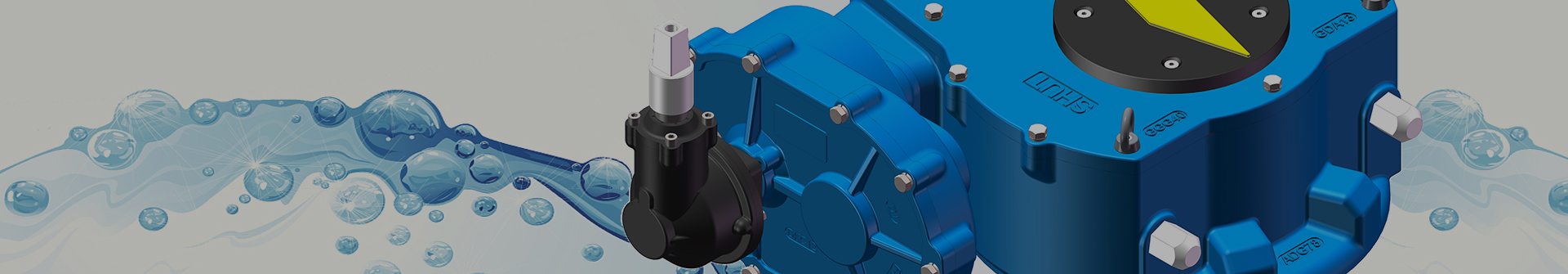

Worm gear reducers are popular for their compact and robust design. A gear mechanism consists of a worm that meshes with a worm wheel to create rotational motion. This design allows for higher torque output compared to other types of gear reducers. Additionally, worm gear reducers are known for their ability to withstand heavy loads and provide smooth rotation, making them suitable for demanding applications.

One of the main advantages of a high-performance worm gear reducer is its efficiency. These gear reducers offer high gear ratios for substantial torque multiplication. This means that small motors can be used to drive loads that would otherwise require larger motors. This not only saves space, but also reduces energy consumption and costs. The efficiency of worm gear reducers can result in significant savings in power consumption, making them a cost-effective choice for many industrial applications.

In addition to efficiency, high-performance worm gear reducers also have excellent reliability. The compact design and high-quality materials used in the construction ensure that these gear reducers can handle harsh conditions and heavy loads without compromising performance. Worm gear reducers are designed to provide long-term smooth and stable operation, reducing the risk of downtime and maintenance.

Additionally, worm gear reducers are known for their quiet operation. The meshing of the worm and worm gear produces smooth motion with reduced noise emissions compared to other types of gearboxes. This makes high-performance worm gear reducers ideal for applications requiring low noise levels, such as food processing, HVAC systems, and medical equipment.

The versatility of high performance worm gear reducers make them suitable for a wide range of applications. They are commonly used in conveyor systems, packaging machinery, material handling equipment and machine tools. The high torque output and compact design of these gear reducers make them ideal for heavy-duty applications where space is limited.

When selecting a high performance worm gear reducer, factors such as required torque, input speed and intended application must be considered. Gear ratios, efficiency and load capacity should be carefully evaluated to ensure that the gear reducer meets the specific requirements of the application.

In conclusion, high-performance worm gear reducers are an essential component in many industrial processes. Their compact design, high efficiency and reliability make them an excellent choice for applications requiring heavy loads and high torque output. The quiet operation and versatility of these gear reducers further enhances their appeal in various industries. When selecting a high-performance worm gear reducer, it is critical to consider the specific requirements of the application to ensure optimum performance and efficiency.

Post time: Aug-29-2023