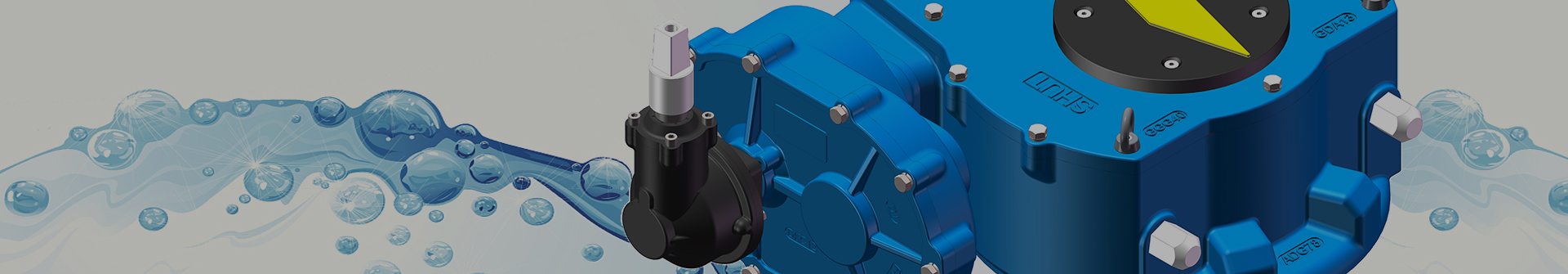

Butterfly valve gearboxes play a vital role in a variety of industrial applications, providing a reliable and efficient method of controlling fluid flow. These gearboxes are an important component of butterfly valves and are widely used in industries such as oil and gas, water treatment, chemical processing and power generation. In this blog, we will explore the importance of butterfly valve gearboxes and their impact on industrial operations.

First and foremost, butterfly valve gearboxes are designed to provide precise control of the opening and closing of the butterfly valve. These valves are typically used to regulate the flow of liquids, gases, and steam in pipelines, with the gearbox responsible for converting operator input into the desired valve position. This level of control is critical to maintaining the efficiency and safety of industrial processes.

One of the main advantages of butterfly valve gearboxes is their ability to provide high torque output. This torque is necessary to overcome resistance within the valve, especially in applications with high fluid pressures or large valve sizes. The transmission ensures smooth and reliable valve operation, even under challenging conditions, thereby increasing the overall efficiency of the system.

In addition to torque output, butterfly valve gearboxes are designed to provide precise positioning of the valve disc. This is essential to achieve precise flow control and ensure that the valve can fully close when necessary. The transmission’s ability to maintain desired valve positions is critical to preventing leaks, reducing energy consumption and optimizing overall system performance.

Additionally, butterfly valve gearboxes are designed to withstand the harsh operating conditions commonly found in industrial environments. They are made from durable materials designed to resist corrosion, wear and temperature extremes. This rugged construction ensures reliable operation of the transmission over a long service life, minimizing the need for maintenance and replacement.

Another important aspect of butterfly valve gearboxes is their adaptability to different types of actuators. These gearboxes are available with a variety of drive methods, including manual handwheels, pneumatic actuators, electric actuators and hydraulic actuators. This flexibility allows the valve control system to be customized to meet the specific requirements of the application, whether it is remote operation, fast response or fail-safe functionality.

Additionally, butterfly valve gearboxes contribute to the overall safety of industrial processes. By providing precise and reliable fluid flow control, these gearboxes help prevent accidents, spills and equipment damage. They also play a key role in emergency shutdown systems, where closing valves quickly and accurately is critical to controlling hazardous materials and preventing catastrophic events.

In summary, butterfly valve gearboxes are an important component in industrial applications, providing the necessary torque, accuracy, durability and safety features to control butterfly valves. Their impact on the efficiency, reliability and safety of industrial processes cannot be overstated, making them vital to many industries. As technology continues to advance, we can expect to see further innovations in butterfly valve gearbox design, further enhancing its performance and capabilities in industrial environments.

Post time: Apr-28-2024