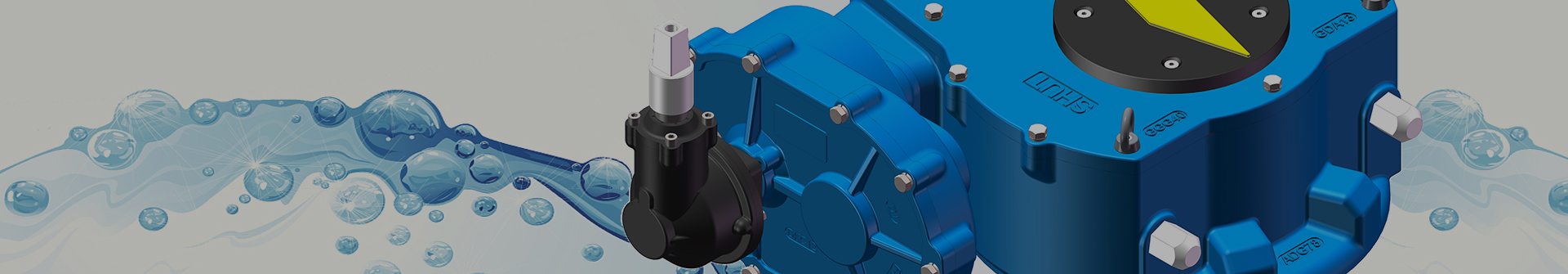

In the field of industrial automation, pneumatic actuators play a vital role in converting energy into mechanical motion. Among the various types of pneumatic actuators, single-stage manual pneumatic actuators stand out for their simplicity and efficiency. In this blog, we will explore the functions and applications of single-stage manual pneumatic actuators, elucidating their importance in the industrial sector.

What is a single-stage manual pneumatic actuator?

A single-stage manual pneumatic actuator is a device that uses compressed air to produce motion. Unlike complex multi-stage actuators, single-stage variants operate with a simple mechanism, making them a popular choice for a variety of industrial applications. By harnessing the power of compressed air, these actuators efficiently convert energy into mechanical force, enabling precise control and movement in industrial processes.

simple power

One of the main advantages of single-stage manual pneumatic actuators is their simplicity. With fewer components and a simple design, these actuators are easy to install, operate and maintain. This simplicity not only reduces overall implementation costs, it also minimizes the risk of potential failures, ensuring reliable performance in industrial environments.

Precise control and versatility

Despite their simplicity, single-stage manual pneumatic actuators provide precise control of the movement and force they produce. This level of control is critical in a variety of industrial processes where precision and consistency are critical. In addition, these actuators are versatile and capable of performing a variety of tasks, from simple switching operations to more complex positioning and manipulation tasks.

Applications in various industries

The versatility and reliability of single-stage manual pneumatic actuators make them indispensable in numerous industries. From manufacturing and assembly lines to packaging and material handling, these actuators play a vital role in automating processes and improving overall efficiency. Their ability to provide consistent and controlled motion makes them ideal for applications such as valve actuation, conveyor systems and robotic manipulators.

Improve safety and efficiency

In addition to functional benefits, single-stage manual pneumatic actuators help improve the overall safety and efficiency of industrial operations. By automating repetitive tasks and reducing the need for manual intervention, these actuators help minimize the risk of workplace accidents and injuries. Additionally, its energy-efficient operation and low maintenance requirements help improve the overall efficiency of industrial processes, resulting in cost savings and increased productivity.

Looking to the future

As technology continues to advance, the role of single-stage manual pneumatic actuators in industrial automation is expected to continue to evolve. As innovations in materials, designs, and control systems continue, these actuators will continue to provide enhanced performance and functionality, further expanding their applications in various industries.

In summary, single-stage manual pneumatic actuators prove the simplicity and efficiency of industrial automation. Their ability to harness the energy of compressed air and convert it into precise mechanical motion makes them indispensable in a wide range of industrial applications. As the industrial landscape continues to evolve, these actuators will undoubtedly remain the cornerstone of efficient, reliable automation.

Incorporating single-stage manual pneumatic actuators into industrial processes can improve safety, efficiency and overall performance. Their simplicity, versatility and precise control make them valuable assets in the pursuit of simplifying and automating operations. As industries continue to embrace automation and look for ways to optimize processes, the importance of single-stage manual pneumatic actuators will only continue to grow.

Post time: Mar-22-2024