Keywords: multi-turn spur gearbox

introduce:

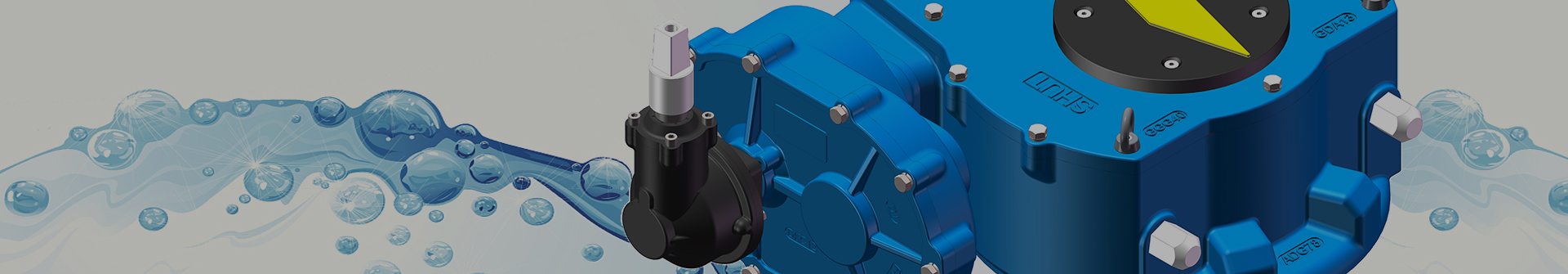

In today’s modern industrial landscape, optimizing efficiency is critical to staying competitive and meeting rising demand. Multi-turn spur gearboxes are one of the vital components that play an important role in achieving operational excellence. The purpose of this blog post is to explore the features and benefits of this breakthrough technology, shed light on its impact on various industries, and why it has become a game-changer in improving productivity.

Part 1: Understanding Multi-Turn Spur Gearboxes

A multi-turn spur gearbox is a key mechanical system designed to transmit power between parallel shafts, allowing rotation at different speeds. It consists of a series of interlocking gears that provide a versatile solution for torque conversion while maintaining efficiency.

Section II: Advantages and Applications

2.1 Enhanced Speed Control and Accuracy

Multi-turn spur gearboxes provide precise speed control, enabling industries to accurately regulate the rotational output of machinery. This capability is especially valuable in processes requiring high precision, such as CNC machining, robotics, and automated assembly lines.

2.2 Increase torque output

Multi-turn spur gearboxes provide torque multiplication for easy operation of heavy-duty applications. By utilizing torque precisely, these gearboxes ensure smooth operation of even the most demanding machinery, preventing unnecessary stress on components and improving overall life.

2.3 Optimum power transmission

One of the main advantages of multi-turn spur gearboxes is their power transmission efficiency. Unlike other gear systems such as bevel or worm gears, spur gearboxes transmit rotational motion with minimal losses, resulting in superior power utilization. This advantage has proven particularly beneficial in energy-intensive industries such as renewable energy, where maximizing power conversion is critical.

2.4 Abundant industry applications

Multi-turn spur gearboxes are widely used in various industries. This versatile technology enables precise control, reliable torque transfer and unrivaled efficiency in every industry, from automotive manufacturing and aerospace engineering to heavy machinery production and packaging.

Section 3: Key factors for selecting a suitable multi-turn spur gearbox

3.1 Load capacity and durability

It is critical to select a multi-turn spur gearbox that matches the specific load requirements of a particular application. Knowing what is required of a gearbox and ensuring it is durable enough to handle the load will prevent premature wear and failure.

3.2 Speed ratio and speed requirements

Every industry has unique speed and ratio requirements. Prioritizing transmissions that offer multiple ratio options to accommodate both high and low speed operation will ensure optimum performance and flexibility.

3.3 Maintenance and lifetime

When investing in a multi-turn spur gearbox, its maintenance requirements and overall service life must be considered. Choosing a gearbox made from high-quality materials, manufactured with precision and requiring minimal maintenance can significantly reduce downtime and increase productivity.

Section 4: Future growth and progress

As the industry continues to evolve, so will the multi-turn spur gearboxes. Advances in materials science, lubrication technology and precision manufacturing will pave the way for more efficient and stronger transmissions. These developments will enable industries to further optimize operations, reduce costs and minimize environmental impact.

in conclusion:

In a rapidly evolving industrial environment, multi-turn spur gearboxes serve as catalysts for increased efficiency and precision. Its ability to amplify torque, ensure optimum power transfer and adapt to different applications makes it an invaluable tool in numerous industries. As technology advances, multi-turn spur gearboxes will continue to revolutionize industrial performance, enabling organizations to meet future demands while maximizing competitive advantage.

Post time: Aug-16-2023