Part-turn worm gear boxes are an essential component in many manufacturing and industrial processes. These gear boxes translate rotational motion from a drive shaft to a driven shaft, with the use of a worm gear and worm wheel. Understanding the unique benefits of part-turn worm gear boxes is crucial for engineers, machine builders, and maintenance personnel in industrial settings.

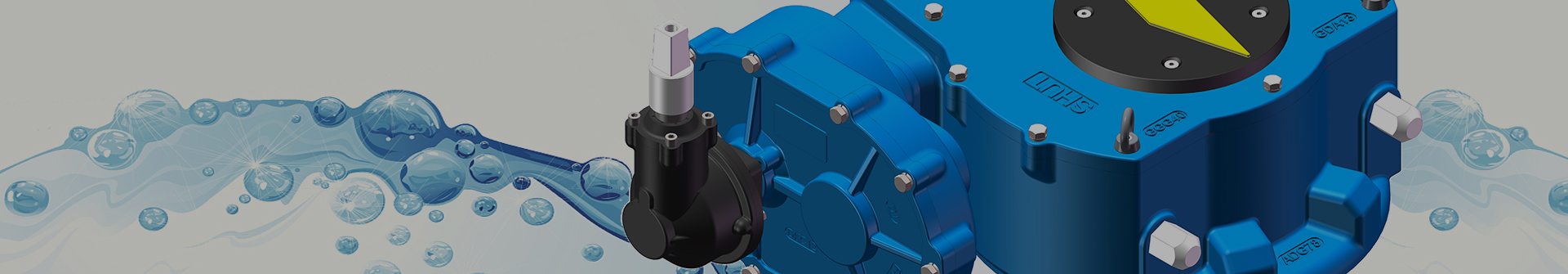

Part-turn worm gear boxes offer several advantages over other types of gear boxes. One of the primary benefits is their compact design, which allows for easy installation in tight spaces. The worm gear and worm wheel are contained within a sealed housing, which helps to prevent contamination from dust or other debris. This makes them ideal for critical processes that require precise and reliable performance.

Another significant advantage of part-turn worm gear boxes is their high reduction ratios. This means that a small input torque can generate a large output torque. Part-turn worm gear boxes are also highly efficient, with less energy loss due to friction compared to other types of gear boxes.

Part-turn worm gear boxes are commonly used in applications where a quarter-turn or less of rotation is needed. For example, they are often used in valves, dampers, and other equipment that requires precise and controlled movement. In these applications, part-turn worm gear boxes provide accurate positioning and ensure that the equipment operates correctly.

For applications that require even more precise control, part-turn worm gear boxes can be combined with other components such as servo motors or position sensors. This allows for even greater accuracy and control over the output motion.

When selecting a part-turn worm gear box for an application, it is important to consider several factors. These include the required output torque, speed, and the specific application requirements. It is also essential to consider the type of environment the gear box will be exposed to and the level of maintenance required.

Regular maintenance is crucial for ensuring the long-term performance of part-turn worm gear boxes. This includes regular lubrication and inspection for wear and damage. Proper maintenance will extend the lifespan of the gear box and help prevent failure or downtime in critical systems.

In conclusion, part-turn worm gear boxes play a vital role in industrial applications where precise rotational motion is necessary. Their compact design, high reduction ratios, and efficiency make them ideal for critical processes that require precise and reliable performance. Proper selection and maintenance of these gear boxes will ensure optimal performance and longevity for industrial applications.

Post time: Apr-19-2019